プロセス強化を目指したマイクロ化学プロセスの開発

メンバー: 桜井誠

分野: ナノ・マイクロ科学、プロセス・化学工学、総合工学

所属: 工学研究院

キーワード: プロセス強化、 マイクロリアクター、 構造体触媒、 非定常操作、 process intensification、 micro reactor、 structured catalyst、 non-steady operation

ウェブサイト:

研究概要

化学プロセスの大幅な効率向上を実現するべく、プロセス強化の概念に基づいた高性能マイクロ化学プロセス開発に向けた研究を実施しています。プロセスの構成要素を空間スケールと時間スケールについてマルチスケールでとらえ、様々なスケールでの要素の相互作用につい検討し、プロセスの最適設計を目指します。具体的には触媒反応プロセスについて、装置設計と操作設計の観点からマルチスケールでアプローチし、以下の研究を実施しています。

1) 構造体触媒を用いたマイクロリアクターの研究

2) 酵素担持マイクロリアクターの研究

3) 温度周期操作マイクロリアクターの研究

4) 熱交換型マイクロリアクターの研究

主要論文・参考事項

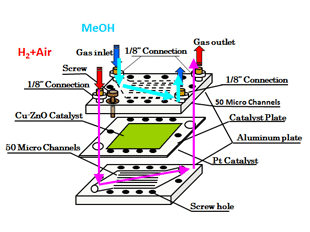

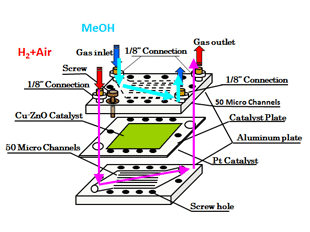

1) “Development of the Heat Exchanger Type Microreactor Using Anodized Aluminum Catalyst for Compact Fuel Cell”, Y. Yonekura, M. Sakurai and H. Kameyama, Abstract of the 11th International Conference on Microreaction Technology(IMRET 11), Paper No. P3-2(2010)

2) “Operating Temperature Conditions for Periodic Temperature Cycling in a Microreactor”, Toru Nakano, Makoto Sakurai and Hideo Kameyama, Journal of Chemical Engineering of Japan, 45(2), 89-93(2012)

3) “Development of a Microreactor with a Structured Catalyst”, Shogo Shimada, Makoto Sakurai and Hideo Kameyama, Journal of Flow Chemistry, 3 (3), 99-102(2013)

4) “Parametric Study of Periodic Temperature Cycling Using Microreactor”, Makoto SAKURAI, Hiroki OKU and Hideo KAMEYAMA, Journal of Chemical Engineering of Japan, 47(2), 207-211(2014)

お問い合わせ先

東京農工大学・先端産学連携研究推進センター

urac[at]ml.tuat.ac.jp([at]を@に変換してください)

Development of micro chemical process towards the process intensification

Research members: Dr. Makoto Sakurai

Research fields: Nano/Micro science, Process/Chemical engineering, Integrated engineering

Departments: Institute of Engineering

Keywords: process intensification, micro reactor, structured catalyst, non-steady operation

Web site:

Summary

In order to realize the drastic improvement of chemical process, research towards the highly efficient micro chemical process development based on the concept of process intensification is conducted. The component of a process is considered on a multi scale which consists of space and time. Our aim is the optimal design of a process considering the interaction of various scale of those components. The multi scale approach is conducted in a view point of the equipment design and the operation design and the following researches are ongoing.

1) Development of micro reactor with structured catalyst

2) Development of micro reactor with immobilized enzyme

3) Study on periodic temperature cycling with micro reactor

4) Development of heat exchanger type micro reactor

Reference articles and patents

1) “Development of the Heat Exchanger Type Microreactor Using Anodized Aluminum Catalyst for Compact Fuel Cell”, Y. Yonekura, M. Sakurai and H. Kameyama, Abstract of the 11th International Conference on Microreaction Technology(IMRET 11), Paper No. P3-2(2010)

2) “Operating Temperature Conditions for Periodic Temperature Cycling in a Microreactor”, Toru Nakano, Makoto Sakurai and Hideo Kameyama, Journal of Chemical Engineering of Japan, 45(2), 89-93(2012)

3) “Development of a Microreactor with a Structured Catalyst”, Shogo Shimada, Makoto Sakurai and Hideo Kameyama, Journal of Flow Chemistry, 3 (3), 99-102(2013)

4) “Parametric Study of Periodic Temperature Cycling Using Microreactor”, Makoto SAKURAI, Hiroki OKU and Hideo KAMEYAMA, Journal of Chemical Engineering of Japan, 47(2), 207-211(2014)

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)