金属板材の面内反転負荷試験による高精度材料モデリング

メンバー: 桑原利彦

分野: 機械工学

所属: 工学研究院

キーワード: plasticity、 sheet metal、 stress reversal、 combined hardening、 Bauschinger effect、 SD effect

ウェブサイト:

研究概要

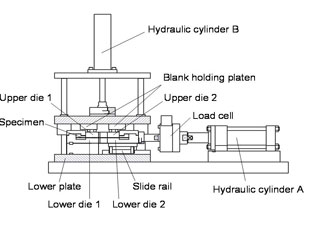

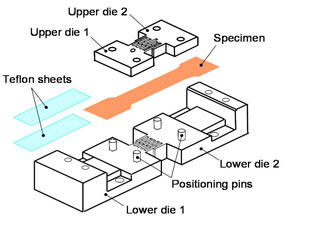

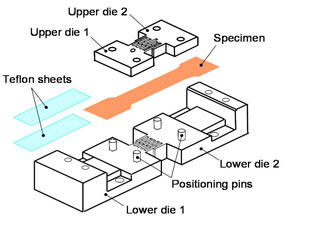

金属板材に面内反転負荷を与え、応力-ひずみ曲線を連続測定するための試験方法を確立した。バウシンガ効果や弾性率の塑性ひずみ依存性などを高精度に測定でき、成形シミュレーションの高精度化に必須となる材料モデルの精度向上に役立つ。開発した金属板材の面内反転負荷試験機を図1と図2に示す。図1は櫛歯金型、図2は試験機の外観である。くし歯金型は一対の下金型と一対の上金型から構成されている。試験片は上金型と下金型の間に挟まれ、油圧シリンダBにより試験片にしわ抑え力を負荷する。この状態で、油圧シリンダAによって下金型2を左右に駆動する。これにより、試験片を座屈させることなく、試験片の面内に引張・圧縮の連続反転負荷を加えることができる。ひずみ計測にはひずみゲージを用いる。

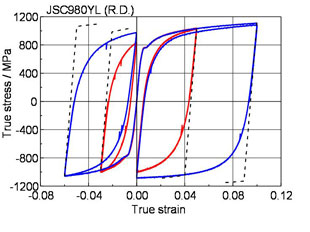

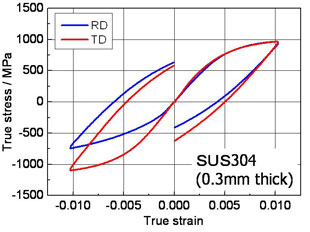

プレス成形中の板材のある部位では、曲げ曲げ戻し変形のように、材料の内部で反転負荷が発生する場合がある。また素材の製造時と加工時で負荷方向が反転する部位もある。このような部位のスプリングバック量を精密に予測するためには、反転負荷に伴う応力低下(バウシンガ効果)や弾性率の低下を精密に測定し、定式化する必要がある。測定例を図3と図4に示す。

主要論文・参考事項

1.Verma, R. K., Kuwabara, T., Chung, K., Haldar, A., 2011. Experimental evaluation and constitutive modeling of non-proportional deformation for asymmetric steels, Int. J. Plasticity 27, 82-101.

2.Kuwabara, T., Kumano, Y., Ziegelheim, J., Kurosaki, I, 2009. Tension-Compression Asymmetry of Phosphor Bronze for Electronic Parts and its Effect on Bending Behavior, Int. J. Plasticity 25, 1759-1776.

3.Murakoso, S., Kuwabara T., 2009. Measurement and Analysis of Ultra-Thin Austenitic Stainless Steel Sheet under Biaxial Tensile Loading and In- Plane Reverse Loading, J. Solid Mech. Mater. Eng. 3 (12), 1330-1339.

4.Kuwabara, T., Saito, R., Hirano, T., Oohashi, N, 2009. Tension-compression asymmetry of sus304 stainless sheet for electronic parts and its effects on bending and springback behavior, Tetsu-to-Hagan? 95 (11), 732-739. (in Japanese)

5.Kuwabara, T., Morita, Y., Misashita, Y., Takahashi, S., 1995. Elastic-plastic behavior of sheet metals subjected to in-plane stress reversals, J. JSTP 36 (414), 768-774. (in Japanese)

お問い合わせ先

東京農工大学・先端産学連携研究推進センター

urac[at]ml.tuat.ac.jp([at]を@に変換してください)

Advanced material modeling based on in-plane reverse loading test for sheet metals

Research members: Dr. Toshihiko Kuwabara

Research fields: Mechanical engineering

Departments: Institute of Engineering

Keywords: plasticity, sheet metal, stress reversal, combined hardening, Bauschinger effect, SD effect

Web site:

Summary

An in-plane reverse loading test method for sheet metals has been established. This test method enables an accurate measurement of the Bauschinger effect of sheet metals and the strain dependence of the elastic modulus, which determine important material parameters for performing accurate sheet metal forming simulations.

The sheet metal in-plane reverse loading testing machine developed by our laboratory is shown in Figs. 1 and 2. Figure 1 illustrates comb-shaped dies invented to apply an in-plane continuous reverse load to a sheet specimen. Figure 2 is a general view of the testing machine. The dies consists of a pair of die sets: a lower die set and an upper die set. The specimen is placed on the lower die set and fixed at both ends to the die set with chucks. Then the upper die set is put on the specimen, and rollers are placed on top of the upper die set. Finally the hydraulic cylinder B applies a blank holder force to the specimen. Under this state, the lower die 2 is moved right and left with hydraulic cylinder A. This enables a continuous tension-compression reverse load to be applied in-plane to the specimen. The strain is measured using a strain gauge.

In some parts of a sheet metal that is being press-formed, reverse loads such as in bending and unbending could occur inside the material. In some parts, the direction of the load can be reversed between manufacturing the raw material and processing. To precisely estimate the amount of springback in these parts, it is necessary to measure the reductions in stress (Bauschinger effect) and in elasticity with high precision and formulate them. A measurement example is shown in Figs. 3 and 4.

Reference articles and patents

1.Verma, R. K., Kuwabara, T., Chung, K., Haldar, A., 2011. Experimental evaluation and constitutive modeling of non-proportional deformation for asymmetric steels, Int. J. Plasticity 27, 82-101.

2.Kuwabara, T., Kumano, Y., Ziegelheim, J., Kurosaki, I, 2009. Tension-Compression Asymmetry of Phosphor Bronze for Electronic Parts and its Effect on Bending Behavior, Int. J. Plasticity 25, 1759-1776.

3.Murakoso, S., Kuwabara T., 2009. Measurement and Analysis of Ultra-Thin Austenitic Stainless Steel Sheet under Biaxial Tensile Loading and In- Plane Reverse Loading, J. Solid Mech. Mater. Eng. 3 (12), 1330-1339.

4.Kuwabara, T., Saito, R., Hirano, T., Oohashi, N, 2009. Tension-compression asymmetry of sus304 stainless sheet for electronic parts and its effects on bending and springback behavior, Tetsu-to-Hagan? 95 (11), 732-739. (in Japanese)

5.Kuwabara, T., Morita, Y., Misashita, Y., Takahashi, S., 1995. Elastic-plastic behavior of sheet metals subjected to in-plane stress reversals, J. JSTP 36 (414), 768-774. (in Japanese)

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)